What is Preflighting in Printing? See How PrimeCenter Can Automate It

August 21, 2025

As printers, you always strive to get the result you want in printing. You check your files for errors, and you keep doing it until you get the correct form. This is called preflighting. Another technical word used by professional printers. This process helps you avoid costly mistakes like missing fonts, low-quality messages, or wrong colors.

However, when you handle high-volume production, it’s always difficult to check all of them manually. That’s why you need automation. In this article, we will talk about preflighting, and how Caldera PrimeCenter will help you automate this task.

What is Preflighting in Printing?

Preflighting is the process of checking digital print files before they are sent to production to make sure they meet all technical requirements for correct and successful printing. This includes verifying image resolution, fonts, color spaces, bleed, transparency, and file formats, typically in PDF files.

Think of it as a quality control checkpoint: Detecting errors early saves time, ink, media, and money.

Why Preflighting is Crucial in Modern Print Workflows

Due to the speed in which large format printing works today, mistakes become redundant and will lead to:

- Wasted materials due to misprints

- Delays in delivery

- Customer dissatisfaction

- Extra costs from reprints

By applying Preflighting, you can avoid these issues and make sure that your files are ready to hit your RIP.

How Caldera PrimeCenter Automates Preflighting in an Effective Way

To manually preflight all files, you will need to sacrifice an enormous part of your time and that of your team to be able to handle dozens or even hundreds of jobs. This is what Caldera PrimeCenter takes off your shoulders.

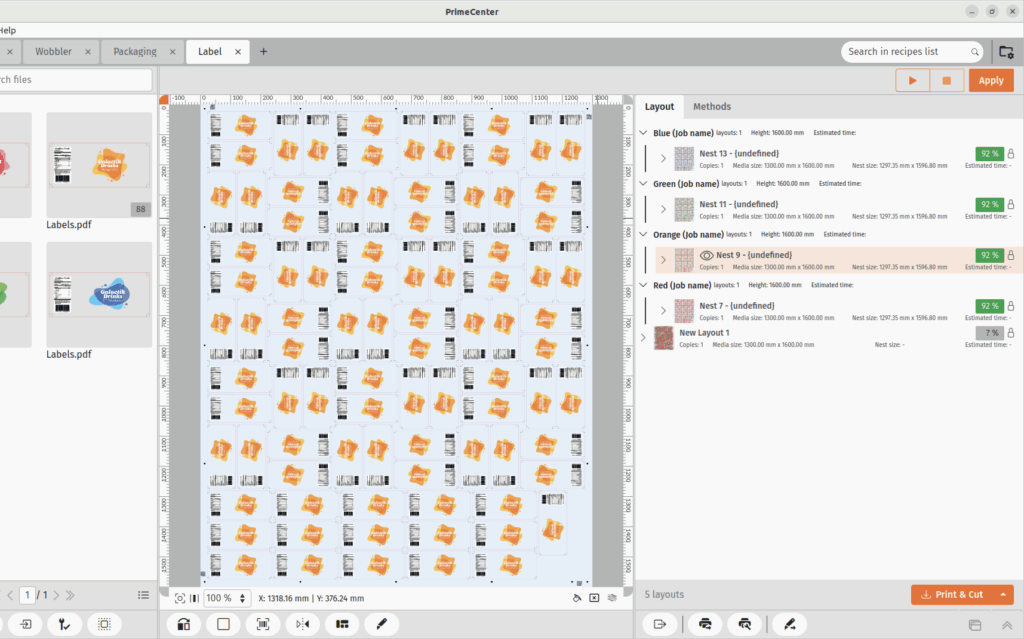

Designed as a prepress automation solution, PrimeCenter simplifies your workflow by automating preflighting, nesting, and job preparation, all before the files even reach your RIP station.

PrimeCenter checks each incoming file against a set of pre-defined rules and instantly flags or fixes common errors, such as:

- Missing or embedded fonts

- Incorrect or unsupported color profiles (e.g., RGB instead of CMYK)

- Low-resolution images below

- Missing bleed or incorrect page sizes

- Transparency issues that might cause printing artifacts

Ready-to-use Preflight Profiles for Different Production Needs

One of PrimeCenter’s strongest advantages is its flexibility. It contains ready-to-use preflight profiles tailored to specific job types, customer requirements, or materials. Whether you’re printing banners, textiles, or rigid signage, PrimeCenter applies different preflight parameters for each category and case.

This means you can eliminate repeated issues and ensure that each job follows the correct technical standards without needing a dedicated operator to check every file.

Smooth Integration with CalderaRIP and Workflow Automation

PrimeCenter integrates with CalderaRIP and hotfolder-based workflows. When a file is dropped into a designated hotfolder, PrimeCenter can:

- Automatically preflight the file

- Nest compatible jobs to reduce media waste

- Generate a report for quality assurance

- Output a print-ready PDF directly to your RIP station

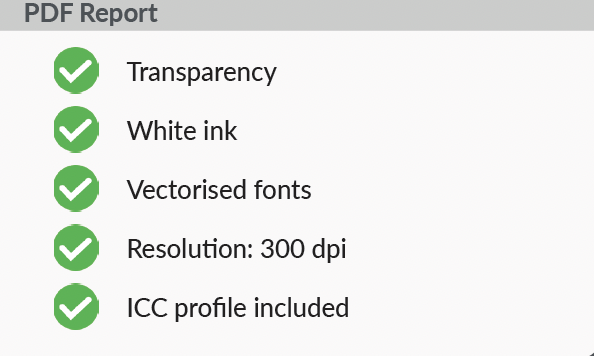

Preflight Reports

With each file processed, PrimeCenter generates a detailed preflight report. These reports outline what checks were processed, what passed or failed, and any actions taken to correct the file.

They’re valuable both for internal quality control and for communicating with customers about file issues.

Preflight Smarter with PrimeCenter

With the growing development we’re witnessing in large-format printing, automation will be your trusted ally. That’s why PrimeCenter becomes the partner of printers who do not want to manually handle preflighting anymore. This is due to the repetitive tasks that their teams have been exposed to. Caldera PrimeCenter sees and detects the details you might neglect when preflighting. This reduces costs and errors while improving your production pace.

What happens when you integrate PrimeCenter into your workflow? You will give your team the time and opportunity to use creativity and improve client satisfaction because no more manual preflighting is needed. Let PrimeCenter take the lead.

Ready to see PrimeCenter in action?

Related articles