Best practices to streamline your Motorcycle wrapping production

May 15, 2024

What is Motorcycle wrapping?

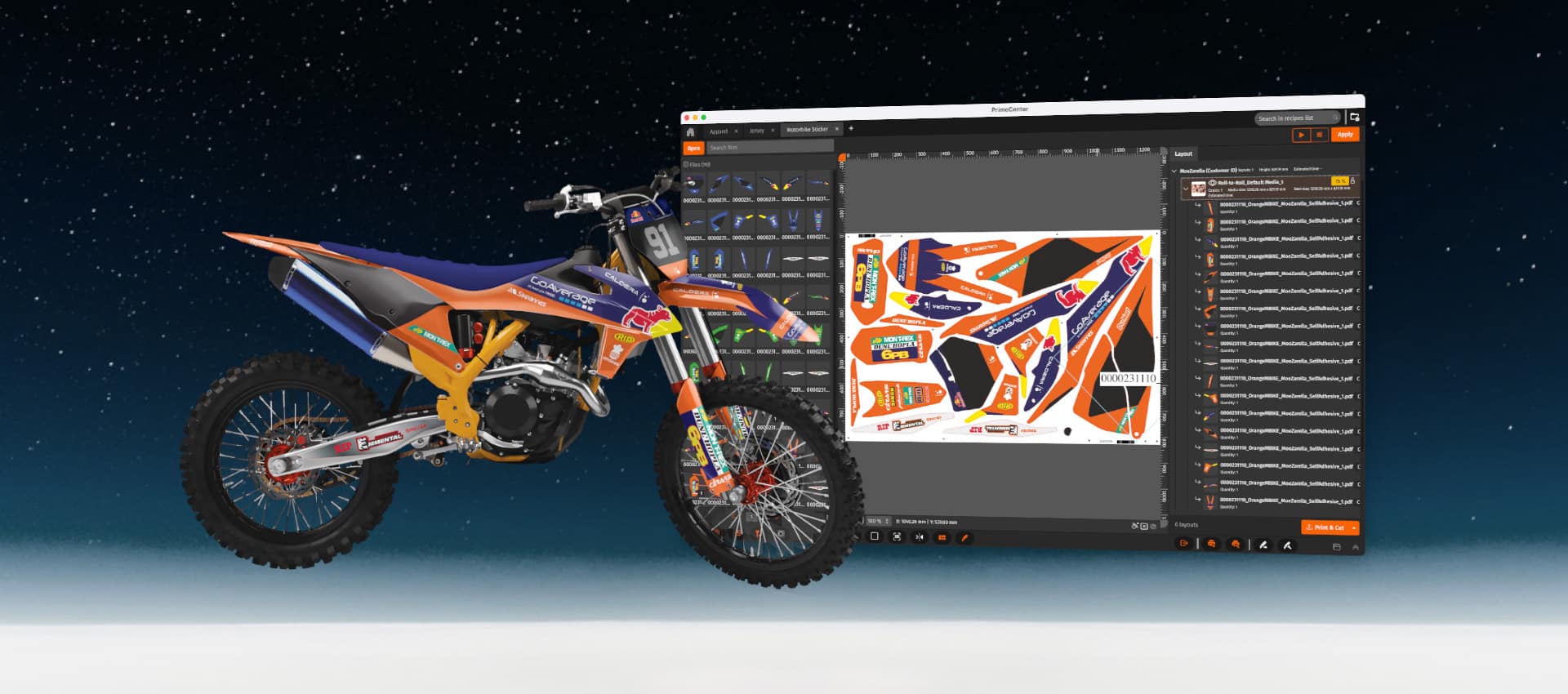

Motorcycle wrapping involves applying a specialized vinyl film to the surface of a motorcycle in order to change its appearance, protect its original paint, or add customized graphics or designs. Vinyl wraps are great for customization, as they come in a wide range of colors, finishes, and patterns, allowing riders to personalize their bikes to match their style preferences.

Producing print and cut files for vinyl printing, especially for motorcycle wrapping, can present several challenges due to the complexity of the shapes and contours of motorcycles. Print and cut files need to account for overlaps and bleed areas to ensure that the vinyl film covers the entire surface of the motorcycle without leaving gaps or exposed areas. Failure to properly account for overlaps and bleed can result in uneven coverage and a disjointed appearance.

In this article, we show you how to streamline your vinyl print & cut workflow for significant time and media savings.

How to streamline your Motorcycle Wrapping production

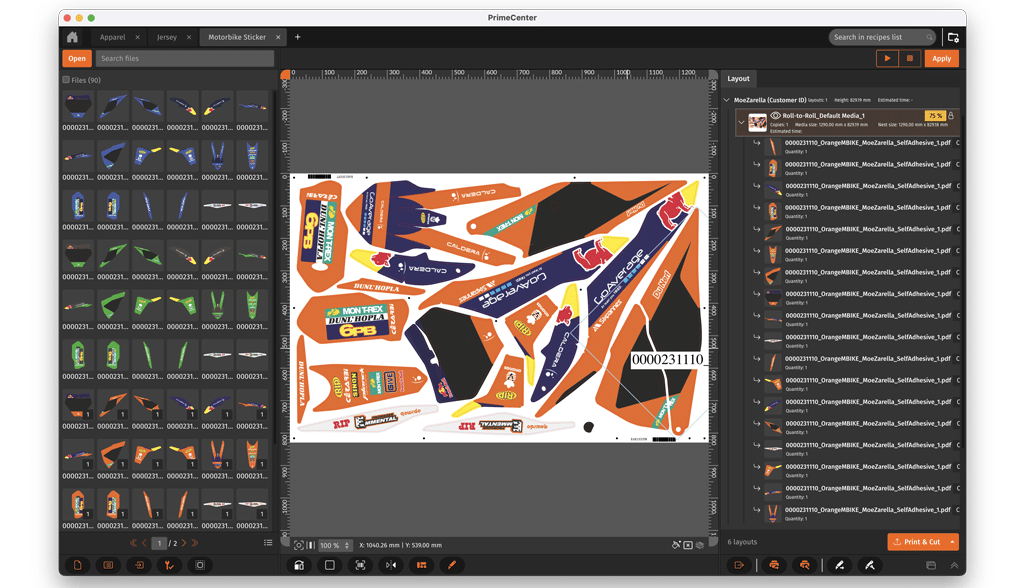

PrimeCenter is a prepress software designed to simplify the preparation of print & cut files. Located upstream of your production, PrimeCenter checks, corrects, sorts, groups and prepares files for production. It helps print service providers to cut down errors, reduce media waste and to increase their productivity.

Used properly, our prepress solution is the key to streamline your entire production workflow. Once your wrapping files have been approved by your customer, you can import them to PrimeCenter to prepare them and make them ready for printing, cutting and weeding.

In just a few steps, PrimeCenter transforms your proofing files into ready-to-print and ready-to-cut layouts!

Use Case – How to prepare Wrapping files with PrimeCenter

1. Check and correct the files

Using PrimeCenter always starts with an input hotfolder to import the files into the software. Then comes preflighting, which is essential for checking PDF standardization and correcting common issues, such as missing cutting instructions, fonts, transparency, resolution, sizes, dimensions or color problems.

After that, we can apply some fixups:

- To automatically separate all shapes into individual files, (which will make it easier for PrimeCenter to nest the pieces during the next step)

- To create cut contours for all the individual pieces of our wrapping design

- And to add print bleed to all the individual pieces.

Using these fixups is a game-changer, especially if you process a number of files every day. Say good-bye to time-consuming, manual processes!

2. Automatically nest, sort & group files

PrimeCenter is great for true-shape nesting, but also enables you to sort and group different files automatically based on specific metadata. In this example, we choose to sort our layouts according to the customer’s name (CustomerID).

All the shapes are nested in an optimized manner to avoid media waste, but also sorted in different layouts according for our different customers. These information will be passed along the production stage for significant time and media savings!

3. Add annotations and cut marks

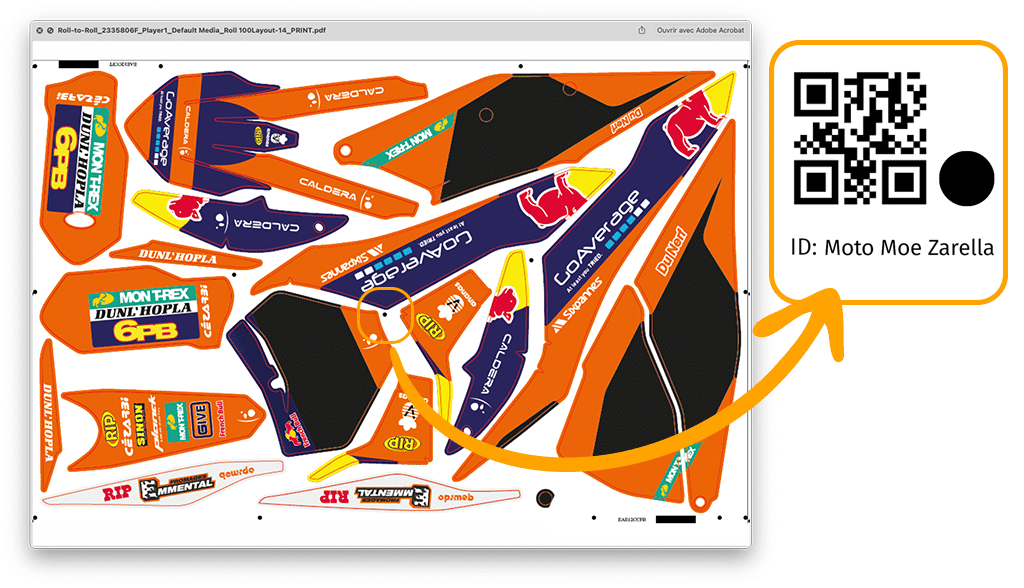

With its array of cutting options, PrimeCenter generates PDF files tailored to your production tools and constraints. You can add annotations, QR codes, optical codes, and more. Optical codes is great for file traceability across your production.

4. Export print & cut files

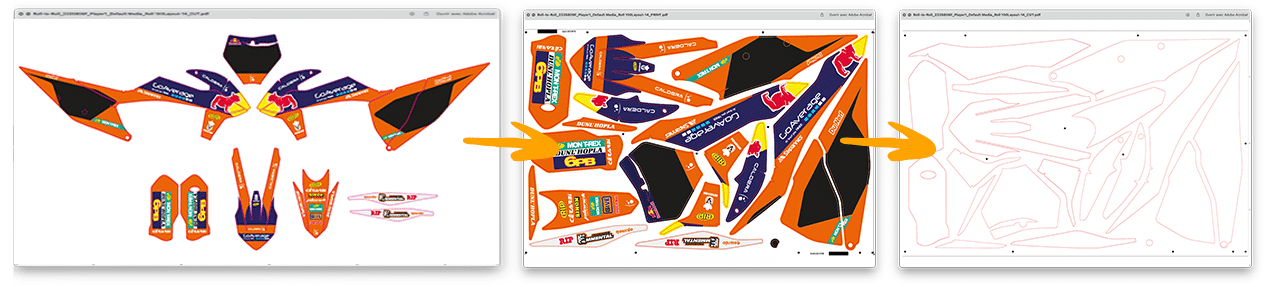

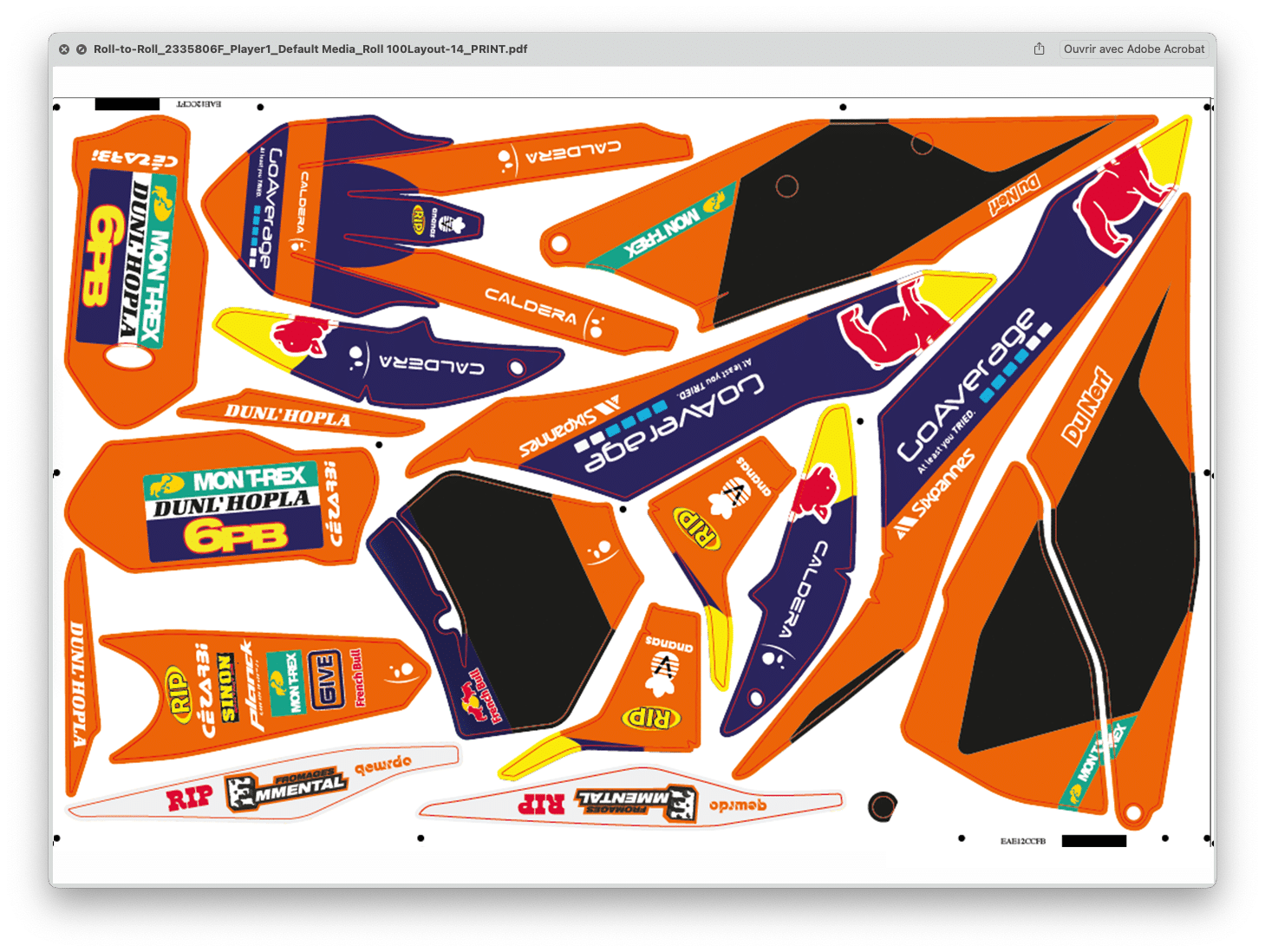

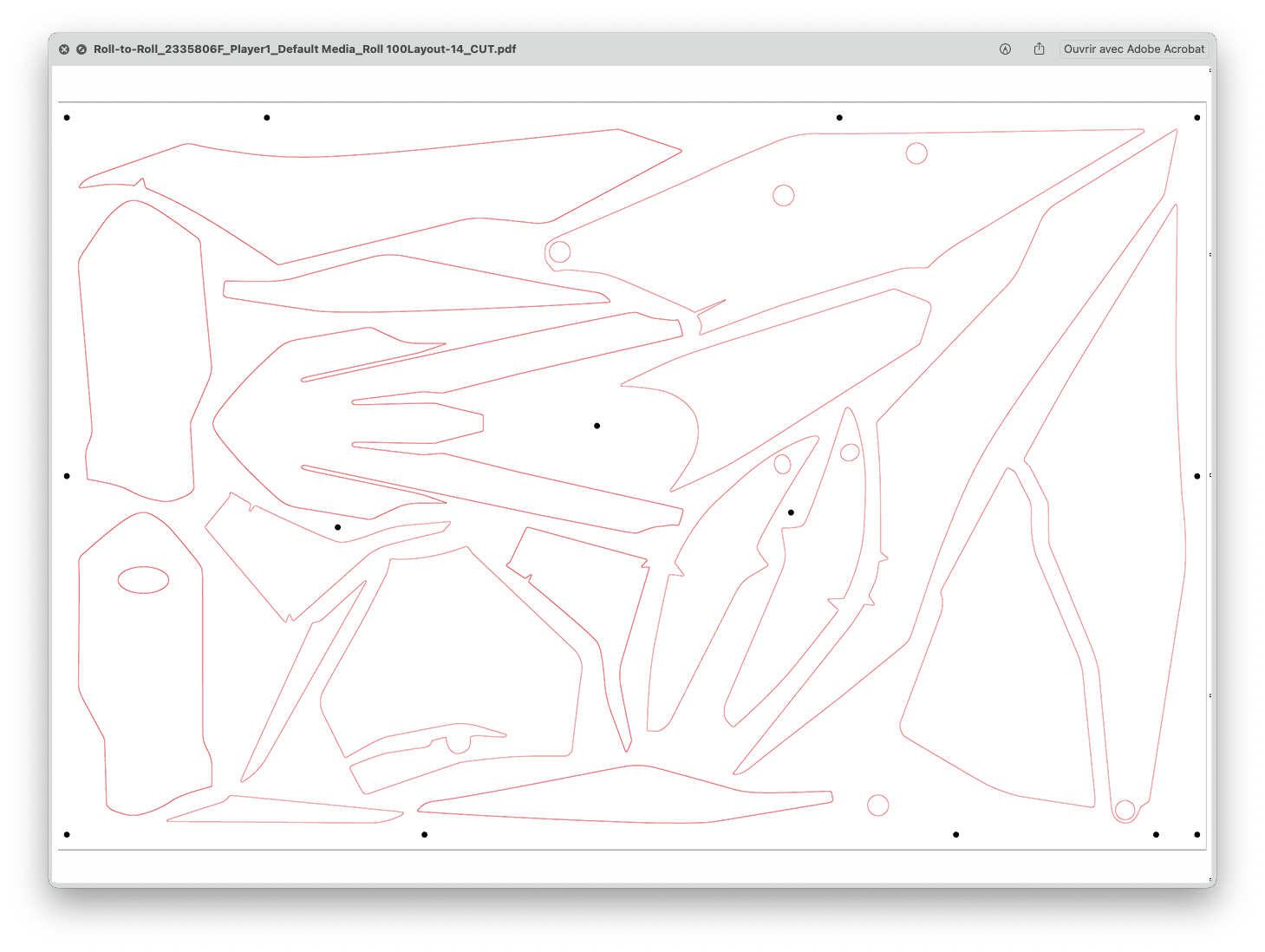

Once we’re happy with your files, we can export them for production. Here, we export our print files, and standard cut files with the contours.

We also export a PDF report listing all the files, the number of copies, the size, media and metadata. This document will help us inspect our layouts before production and save time tracking our various jobs!

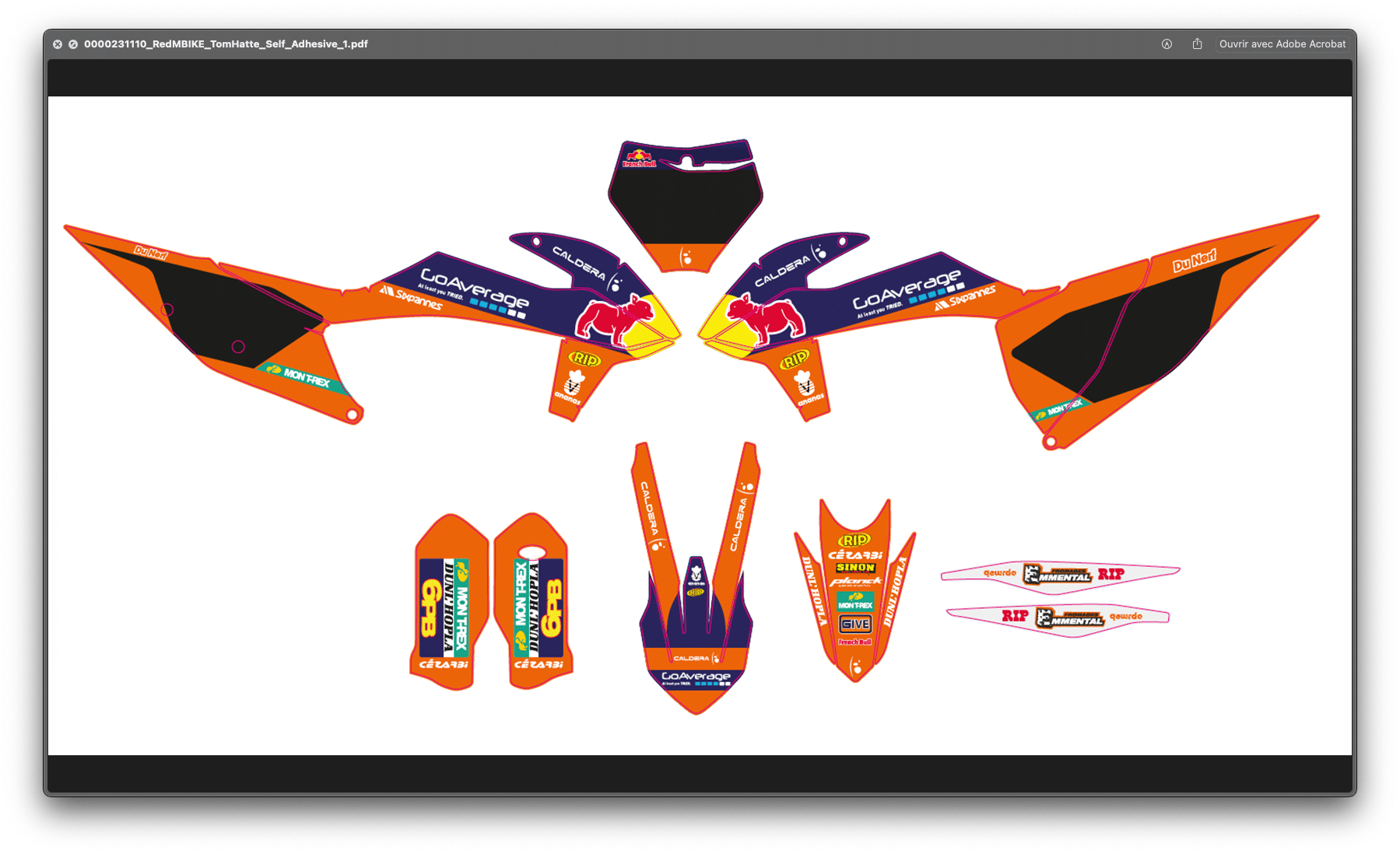

Original file

Print file generated by PrimeCenter

Cut file generated by PrimeCenter

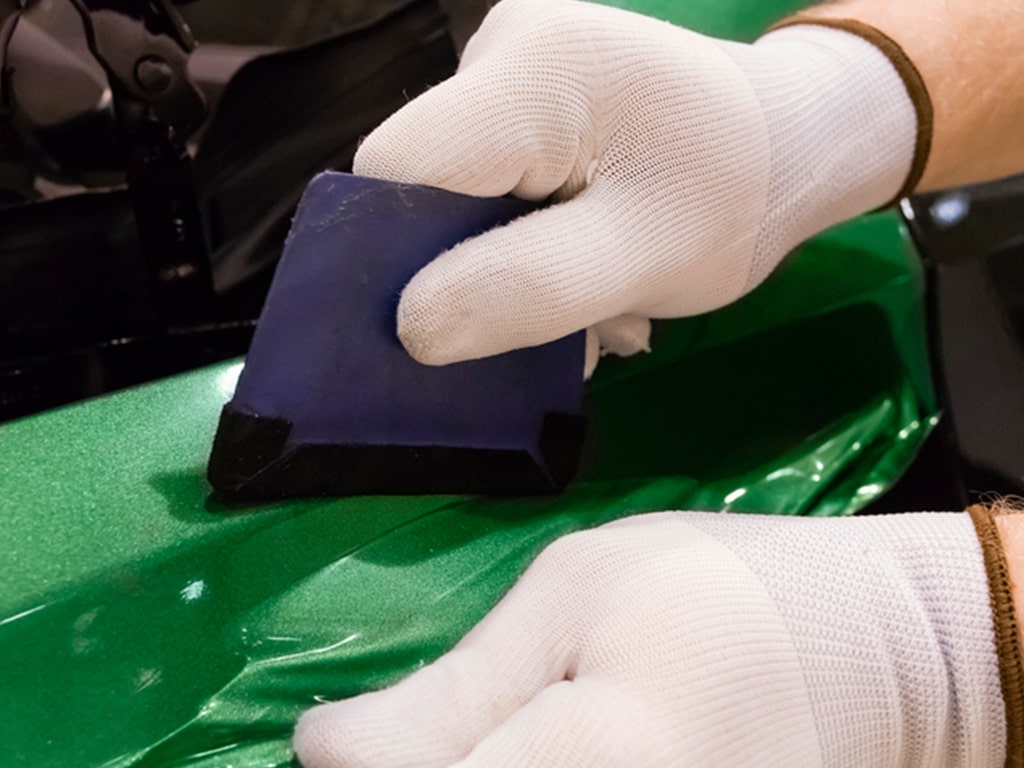

5. Time to print, cut, weed and wrap!

Save time in prepress and file preparation to focus on your production, and deliver all your jobs on time.

Go further with PrimeCenter

Click here to learn more about PrimeCenter, or contact us to book a demo with our workflow specialists!

More tips to boost your workflow

Discover all our tips & tricks to save time, cut down media waste and increase your productivity.

Subscribe to our Newsletter

Stay in touch with our latest product launches, news and events.

Related articles