How to achieve a more sustainable production with your print software

March 12, 2024

The printing industry is currently facing many challenges. Sustainability, durability and eco-friendliness are becoming more and more important for both print shops and consumers. Choosing more eco-friendly materials and energy sources, reducing waste, recycling materials, using less-polluting technologies and printing on-demand have become significant factors for businesses who strive to establish more sustainable production flows.

The software used in digital printing workflows plays a crucial role in managing your resources efficiently. In this article, we will explore how your software can help you achieve a more sustainable print production.

1) The three main criteria of sustainable printing

Achieving a more sustainable print production involves three fundamental criteria:

Limiting the number of prints to the strict minimum

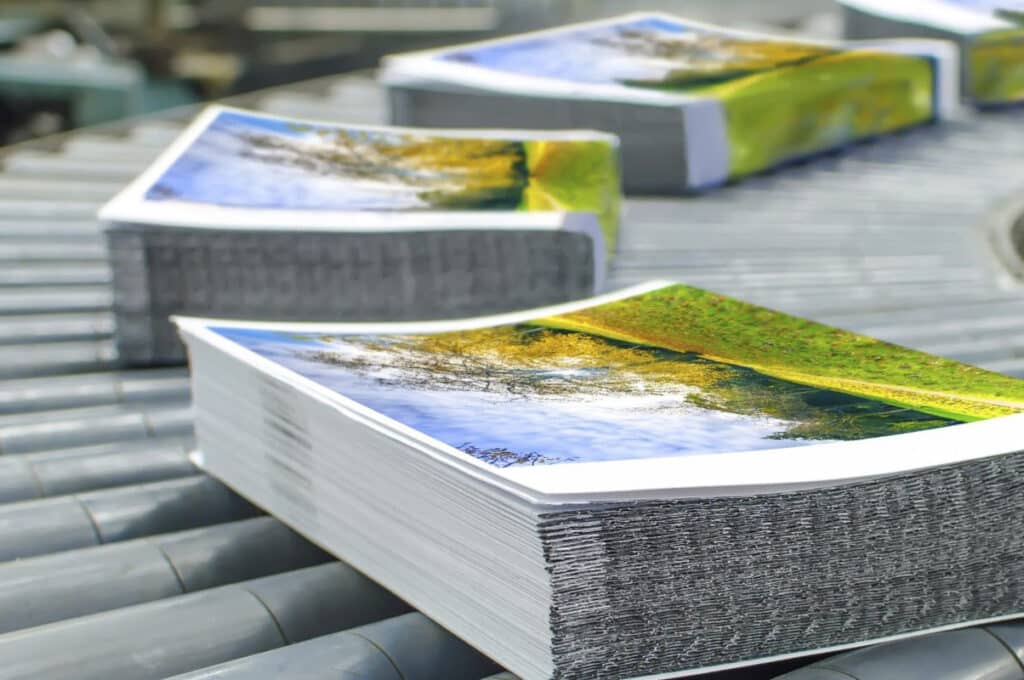

Recent years have seen the rise of on-demand printing, which helps to avoid overproduction, excessive energy consumption, surplus stocks and unnecessary waste.

Choosing materials from responsible and/or recycled sources

The choice of your printing substrate often depends on the project requirements and technical constraints. However, recycled materials, alternative fiber-based materials, biodegradable and organic options are viable choices worth considering for print service providers.

Choosing more sustainable inks

Compared to traditional inks, vegetable-based inks offer more vibrant colors, quick drying, and good resistance to abrasion. They also emit fewer volatile organic compounds (VOCs), thereby helping to preserve air quality. These inks are less harmful, biodegradable, and renewable. However, it is important to verify the manufacturer’s specifications and compatibility with your printing equipment.

What is vegetable-based ink? Vegetable-based ink is obtained from organic compounds derived from plants (cellulose, resin, sugar, starch, etc.). Vegetable oils (linseed, soya, rapeseed, sunflower, coconut, etc.) and resins of natural origin (pine extracts) are blended to produce vegetable-based inks. Although the pigments used are non-renewable synthetic products, they are nonetheless biodegradable.

Other criterias include:

- using renewable sources of electricity

- actively recycling ink cartridges and media

- encouraging awareness by informing consumers about paper consumption, vegetable-based inks and sustainable media

- offering customers data about the environmental footprint of their projects

- designing printed products with recycling in mind (avoid mixing materials that would make recycling harder or impossible)

- reusing recycled materials for short-term campaigns and projects

- considering a take-back program for your customers to encourage recycling

To summarize, adopting a sustainable digital printing workflow relies on choosing better materials, optimizing the use of resources, properly recycling waste and working on consumer awareness. But there’s also another aspect that we have yet to examine for a completely sustainable workflow— and that is the software that are used throughout the digital printing process.

2) How to use your print software for sustainable printing

Can your software be eco-friendly? Indirectly, yes— as it directly gives instructions to your print and cut devices.

There are many types of software involved in a traditional digital printing workflow, such as design software (InDesign, Photoshop, Illustrator, CorelDraw), prepress software (PrimeCenter), and RIP software like CalderaRIP. When used correctly, these software help to optimize ink consumption and material usage to limit prints to the strict minimum.

“Innovation is at the heart of everything Caldera undertakes. We continuously work to provide cutting-edge solutions that meet our customers’ needs. Our software provides them with tools to optimize their production and resources, enabling significant savings while adopting more sustainable practices.”

Sebastien Hanssens, VP Marketing, Caldera

PREPRESS SOFTWARE

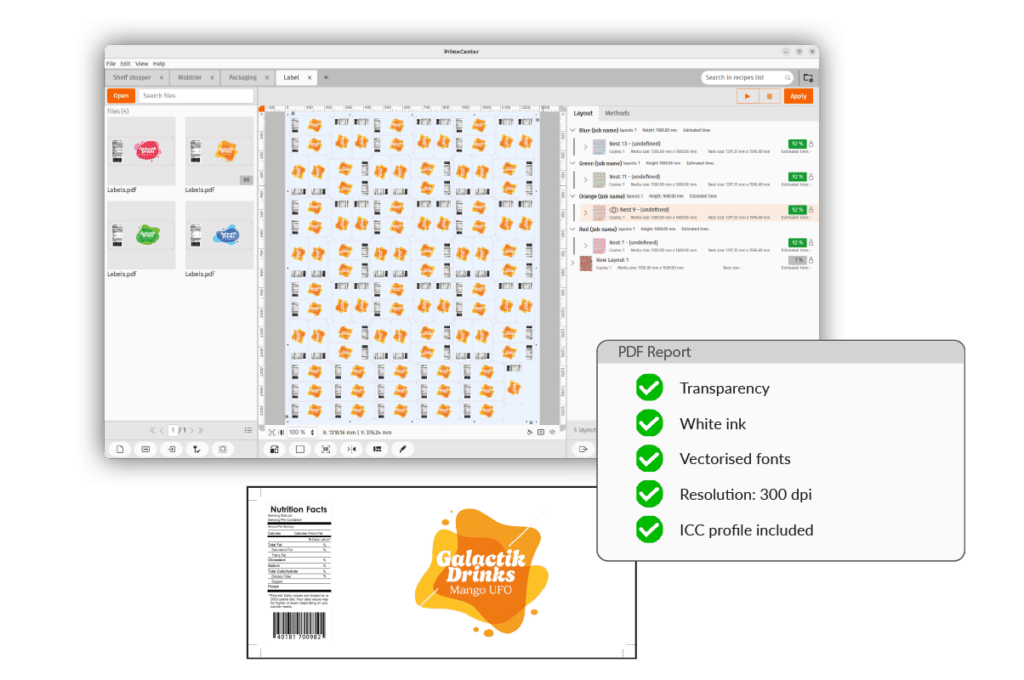

PrimeCenter checks, corrects, groups and prepares files before printing to optimize media usage, reduce waste and avoid costly reprints.

RIP SOFTWARE

CalderaRIP controls printing and cutting processes, and ensures precise colors regardless of the printer-ink-media combination used.

a) How to avoid waste at the prepress stage

Prepress refers to the steps occurring before the actual printing. It includes file verification, nesting, and preparation before production. It plays a crucial role in the quality and consistency of the final output.

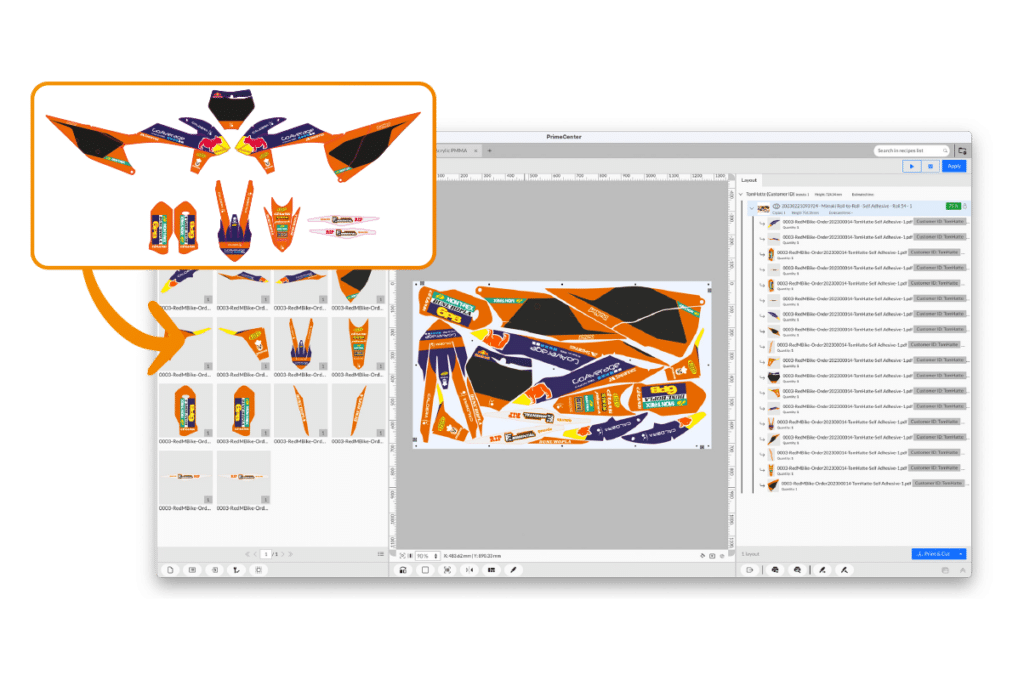

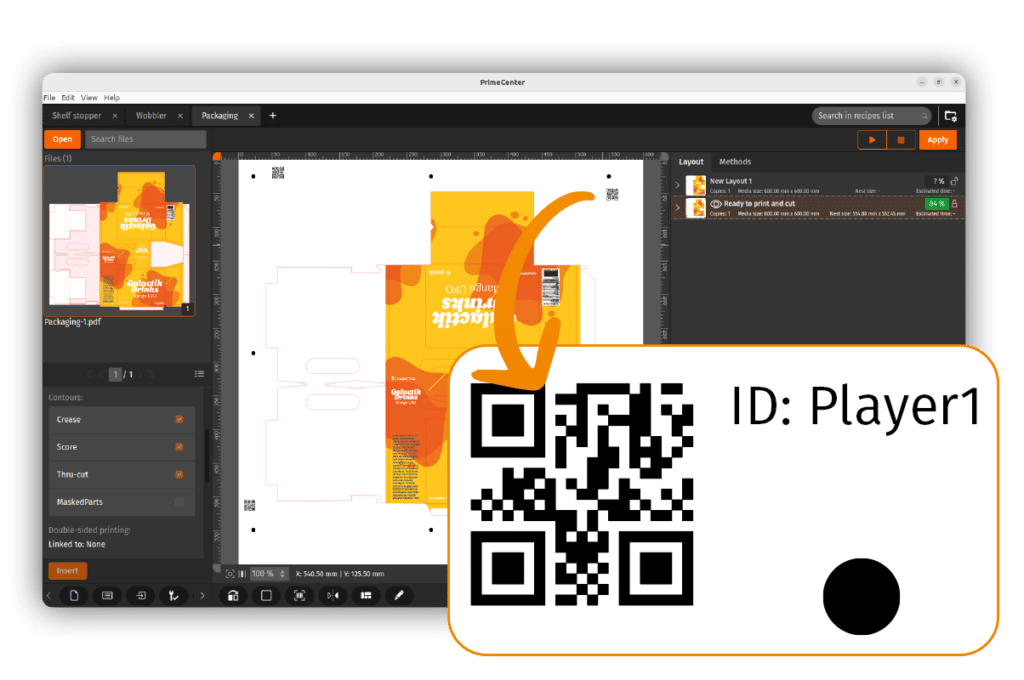

PrimeCenter is prepress software designed to optimize file preparation while anticipating printing, cutting, and finishing steps:

- File verification and correction (preflight) to avoid common issues and costly reprints

- File nesting to reduce waste by up to 20%. Read our dedicated article for more information about nesting and how to optimize media usage.

- Adding print bleed, annotations, barcodes, cut contours, and cut marks to streamline cutting and finishing steps, and avoid errors

- Using metadata to automate file preparation, for example, based on the client or type of media used, to avoid manual errors and waste. Read our dedicated article about how metadata can transform your prepress workflow.

Perform preflight checks to avoid common issues.

Generate perfectly nested layout to make the most of your media.

Add annotations and cut marks to streamline production steps and avoid manual errors.

Once your files are prepared, they are sent to production for printing and cutting. This is when your RIP software typically comes into play.

b) How to reduce ink and media waste with your RIP software

What is a RIP software? The RIP software (Raster Image Processor) is an essential component of the digital printing workflow. It converts text and image data from various formats (PDF, TIFF, JPEG, etc.) into a format that print and cut devices can understand. RIPs control printing and cutting processes and manage colors to achieve perfect colors.

And that’s not all— your RIP software can play a crucial role in reducing the environmental impact of your printshop. There are many RIP software available on the market, including those included directly with your large-format printers, or dedicated solutions like CalderaRIP.

CalderaRIP is a comprehensive RIP software designed to optimize your productivity and color output. It is the preferred choice of printing service providers worldwide for driving any large-format devices, managing colors, and processing print and cut jobs. Intuitive and scalable, CalderaRIP is ideal for both growing businesses and demanding production environments.

Here are some ways CalderaRIP can contribute to your sustainable approach:

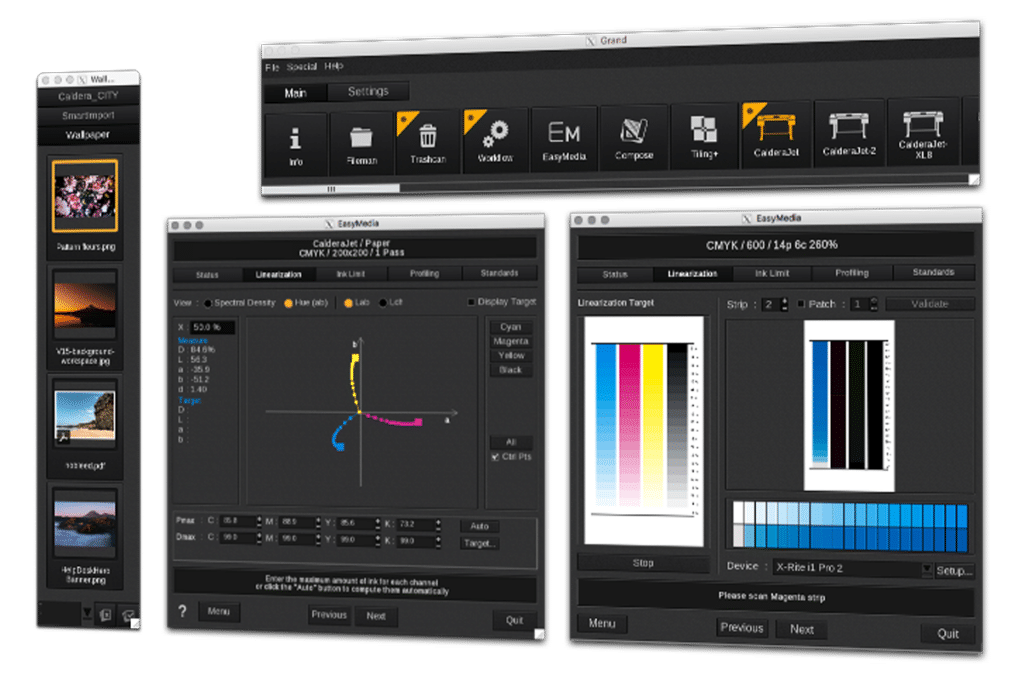

- Color management: CalderaRIP allows precise color management regardless of the printer-ink-media combination used (calibration, ICC profile creation, etc.). Color management reduces the need for frequent trials and adjustments, thus reducing ink and media waste.

- Print quality: CalderaRIP lets you manage many parameters to optimize the print quality, minimizing reprints and associated waste.

- Layout and nesting: CalderaRIP offers layout and nesting features to maximize media usage and reduce waste.

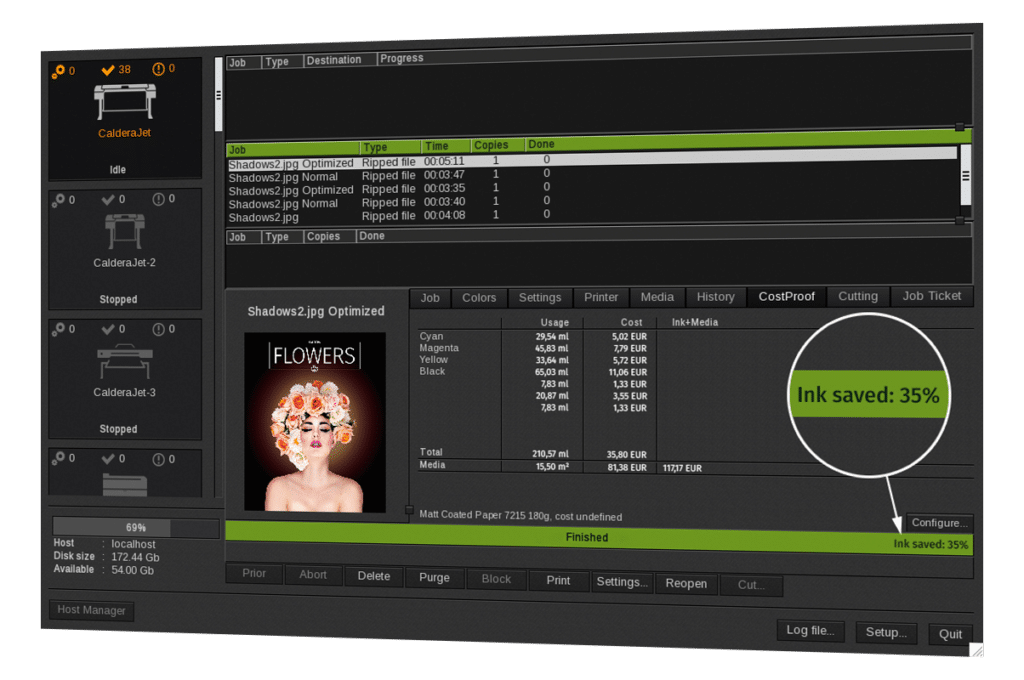

- Ink consumption: CalderaRIP precisely adjusts the amount of ink needed for each printing task to minimize ink consumption and associated costs.

- Production management: CalderaRIP enables you to control your fleet of printers to balance production and optimize the use of your resources. It also allows simulation and preview of the output after ripping, in order to validate and/or adjust the file before printing.

Advanced color management and ICC profiling from the EasyMedia module

Advanced ink consumption optimization from the InkPerformer module

Investing in a high-quality RIP solution optimizes your production processes, resource usage, and waste reduction while improving overall print quality.

Cut down your ink consumption by up to 25% with InkPerformer

InkPerformer is a module that automatically calculates new color combinations to reduce the amount of ink printed on the media– without compromising color accuracy.

- Print more accurate colors (more neutral grays and deeper blacks)

- Reduce your ink consumption

- Reduce your production costs

- Reduce your environmental impact

Interested in InkPerformer? Use our online calculator to estimate your potential return on investment based on your current consumption.

We can help with your digital transformation and sustainable printing projects

In this article, we’ve seen that software can be significant contributors to your sustainable approach. Print software help you optimize media usage, reduce ink consumption and manage your entire production.

Caldera software can help you reduce your environmental impact while making valuable savings.

Have a specific project in mind?

Contact our experts to get custom demos tailored to your needs!

Related articles