Master double-sided printing

December 11, 2023

The secrets of double-sided printing using PrimeCenter

Are your customers asking you for more and more double-sided printing these days? There are so many applications calling for it that it became an essential skill to master. What do we use double-sided printing for? How does it work? Which problems can arise? How PrimeCenter can solve your double-sided printing issues?

What is double-sided printing? What do we use it for?

Double-sided printing refers to the process of printing on both sides of a printable material. You can print the same design on both sides, or a different one on each side.

Mastering this technique enables you to offer your customers a range of products to view from both sides, such as window decorations, stickers, retail and point-of-sale signage, banners, flags and posters. All these products are becoming increasingly popular in healthcare, retail, education, transportation, advertising and exhibition graphics.

The benefit to your client is getting double exposure from one piece of media, while reducing media usage and production time compared with producing two items. The need for less media gives double-sided printing good sustainability and saves on shipping costs. More messaging exposure for a lower cost is beneficial to both you and your customers.

In other words, double-sided printing is an added-value art worth mastering for your printshop!

Print it right on both sides

The challenges of double-sided printing are self-evident:

- Correct positioning: If you’re printing mirror images on each side, they’ll need to be positioned precisely, particularly if the image is going to be cut out. This means the registrations must match exactly when the substrate is flipped. This problem can be magnified if you’re working with clear substrates, such as those used for window graphics. You may find yourself printing several layers of color, all of which need to be matched precisely when the second side comes to be printed. However, it’s well worth making the effort to perfect this technique, as window graphics represent a growing profit opportunity.

- Matching colors: Consistency is the key, in both the placement of the image on both sides, and in maintaining good color management to keep the images identical. Choosing the right substrate for the job can also make a huge difference to the final quality of a double-sided print. For high quality double-sided printing, you’ll need to choose adequate substrate and inks to ensure color consistency. The temptation to cut corners and save money could lead to substandard results.

How does double-sided printing work?

If your printer has double-sided printing capabilities, it will use sensors to read specific marks that guide it to position each image for accurate back-to-back printing. To ensure that it remains accurate over time, the tension control and roll adjustments are set so that the printer can track the media accurately enough for automated double-sided printing.

Your choice of media is also important. While there are a lot of substrates that are suitable for double-sided printing, using double-sided media will give you the best results – such as double-sided blockout vinyl banner materials. Using single-sided media for double-sided printing can result in poor quality printing stemming from issues such as printhead strikes and ink adhesion irregularities.

With a capable printer, double-sided printing is incredibly straightforward. Once you instruct the printer to make a double-sided print, it will print the images for the A side, along with a black reference mark, which will be used to align the B side. When the A side is complete, the printer operator can cut and reload the substrate upside down and start at the reverse end. The reference mark will be face down on the leading edge. Once the printer has located the mark, it will start printing the B side.

Preparing double-sided files with PrimeCenter

When it comes to file preparation for double-sided printing, you’re often trying to optimize image placement manually on your design software to reduce media waste. Then, you export your layout (PDF, EPS, AI) directly to your RIP software to add cut marks and print the files.

Of course, it works.

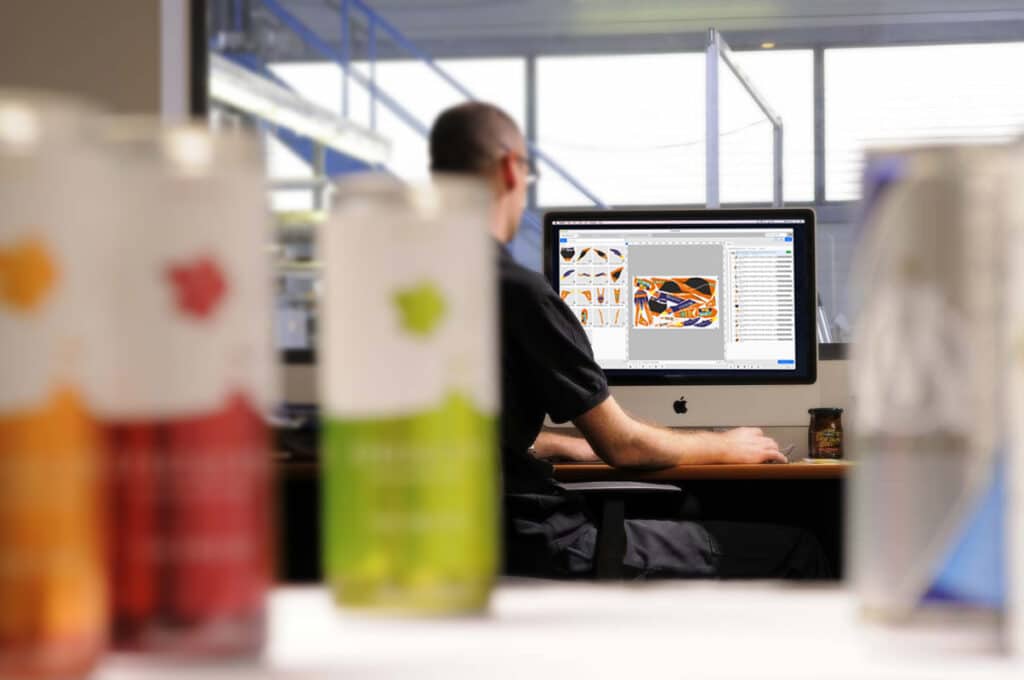

But this workflow is not efficient, especially if the number of orders increases. Manual file optimization, apart from being extremely time-consuming, will never be as efficient as automatic file preparation using a prepress software.

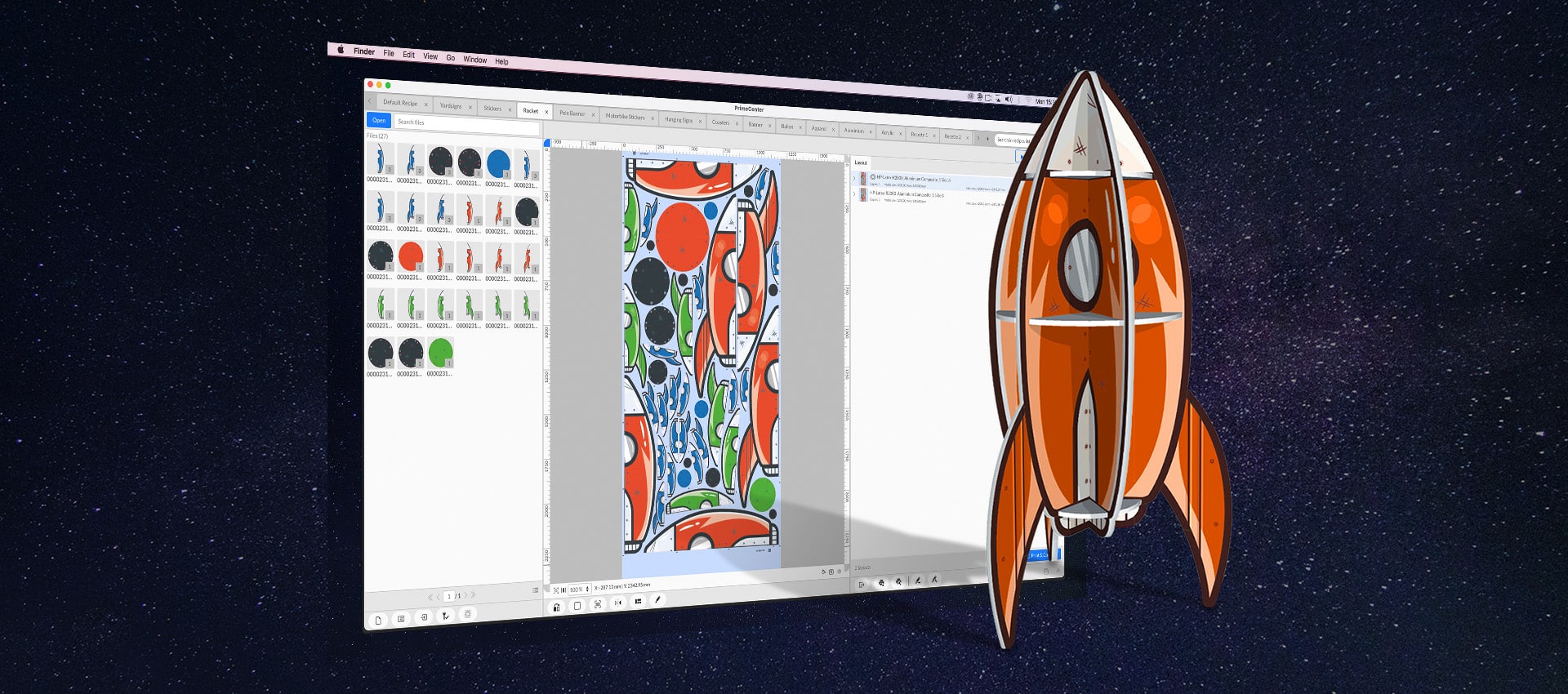

PrimeCenter is a powerful prepress software that optimizes the preparation of print and cut files. It is ideal for print shops who wish to optimize their media usage and overall productivity.

Designed to help prepress operators in their daily tasks, PrimeCenter is a great companion to be more efficient in file preparation, especially if your number of orders increases over time.

When it comes to double-sided printing, PrimeCenter includes a great feature to automate file preparation for double-sided banners, stickers or window graphics:

- Prepare double-sided files with identical designs on both sides, or with different designs on each side

- If both sides are identical, automatically generate side B based on side A

- Automatically position margins and cut marks

- Export double-sided layouts as one multi-page PDF file (to reduce the number of files to manage)

- Choose the flipping direction (depending on how your printer handles the substrate)

- Mirror the backside if needed

Whether you’re printing simple shapes or complex dye-cut outlines with different designs on either side, PrimeCenter can prepare double-sided prints with accuracy and ease, helping you avoid manual errors and save a considerable amount of time.

Want more information? Discover our video explaining how to be more efficient in producing double-sided point-of-sale displays:

Tutorial— Producing double-sided point-of-sale displays

Watch our PrintLab episode explaining how to be more efficient when producing double-sided point-of-sale displays:

- How to efficiently group files for production

- How to prepare files for double-sided printing

- How to match colors on different substrates and printing technologies

Get your free trial of PrimeCenter

Want to save time preparing your files?

Contact us for a custom demo with our specialists and to start your free trial!

Related articles