Spot Color management in DTF Printing: Everything you need to know

April 29, 2025

Color management in DTF printing is an important step. You need to reproduce a color that matches your brand colors, and this is a bit challenging to achieve. To do this, you have to know how to handle spot colors, a term that Adobe explains in detail in their article: spot vs process color.

From team uniforms to branded t-shirts, a consistent and accurate color is non-negotiable. This is where spot color management is a big differentiator in color quality, especially if you have advanced color management tools.

You don’t need to print the most beautiful color, but you have to print a color that represents your brand in the best possible way. Caldera Direct-to-Film is a DTF software that includes automatic spot color conversion. This means that your spot colors are instantly converted to precise ink values to reproduce true-to-brand colors automatically.

In this article, we will explain how automatic spot color conversion works, and we will talk about the other settings offered to you in the Spot Color module found in Caldera Direct-to-Film.

The challenges of Spot Color management in DTF Printing

Spot colors or different shades of colors are often related to brands or teams’ identities. These colors must be accurately defined, regardless of substrate, printer model, or environment.

- Unlike process colors (CMYK), which are blended during printing, spot colors are predefined and require precise management to make sure they stay consistent and accurate when printing and transferring your designs onto fabric.

In DTF printing, poor spot color conversion can result in disappointing print results that fail to meet your client’s expectations. Factors like heat press fluctuations and film quality are already delicate criteria that must be taken into consideration. That’s why a solution that can automatically manage spot color references like Caldera Direct-to-Film is a game-changer that will save you significant time.

Caldera’s advanced Spot Color management for DTF Printing

Caldera Direct to Film brings a high level of control and automation to spot color management. Here’s how it can help you:

Automatic Spot Color conversion

Caldera automatically recognizes and converts spot colors to the closest reference based on the printer’s color profile and film/media settings.

- This automation saves time and reduces manual intervention—perfect for production environments where speed and consistency are a priority.

Fine-Tune Spot Color references

While automation is a fundamental aspect, Caldera also respects the need for customization.

- Users can manually adjust spot color references using the Spot Color module.

- This is useful for last-minute adjustments if a user finds it necessary to change the simulated reference.

Why it matters?

You will no longer have to worry about whether your red looks like drifting toward orange or your blue looks a bit faded than you expected. Automatic spot color conversion is especially useful for businesses in t-shirt printing or DTF printing in general who are preoccupied with DTF workflow production.

What do you have in Caldera Direct-to-Film?

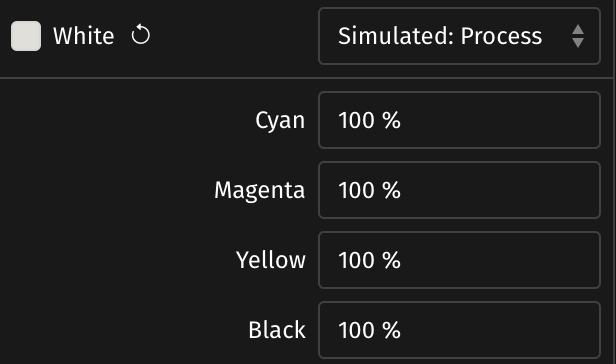

Process ink simulation

The spot color is simulated by blending output inks. You can:

- Manually adjust the ink percentages (Cyan, Magenta, Yellow, and Black)

- Fine-tune the output to match the desired color.

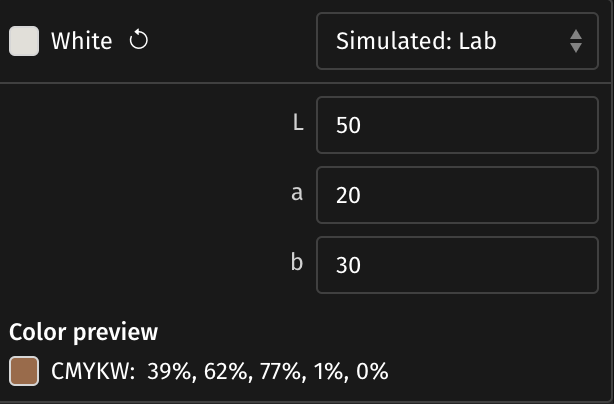

Lab values simulation

Lab values provide a precise color model based on human perception, ensuring an accurate simulation of the spot color. When the Lab simulation is used:

- A color preview is displayed at the bottom of the interface, allowing you to visualize the final color before printing.

- The Lab simulation comes pre-configured with the 50 most commonly used Pantone colors.

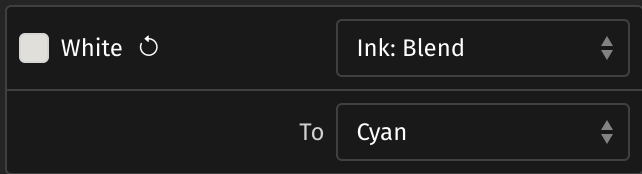

Direct blend

Here, you can blend a spot color into an output ink.

- The process will add ink over the computed output.

- Blending a spot color with process inks is useful for creating custom color effects, softening intense spot colors, and reducing ink costs while maintaining design flexibility.

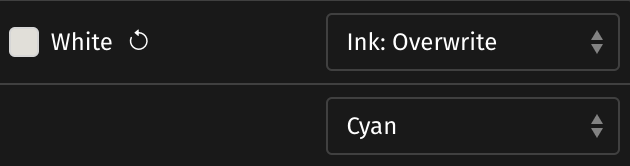

Overwrite channel

Here, you can overwrite a spot color into an output ink.

- The process will replace the computed output with the original spot color.

- Overwriting a spot color fully replaces it with another color, ensuring the correct ink is used when a spot color is unavailable, for example, or when you need to standardize colors for brand consistency or error correction.

Ignore before printing

Here, you can overwrite a spot color into an output ink.

- The process will replace the computed output with the original spot color.

- Overwriting a spot color fully replaces it with another color, ensuring the correct ink is used when a spot color is unavailable.

- For example, or when you need to standardize colors for brand consistency or error correction.

Spot color accuracy is a necessity in DTF printing. Caldera’s automatic spot color conversion, combined with its manual fine-tuning tools, allows DTF printers to deliver accurate and consistent brand colors. Whether you’re printing for companies or a national team, or you want to print your brand on fabric, Caldera ensures your colors stay accurate and consistent through every print and DTF transfer.

Related articles