Automating Print-to-Cut: How Caldera PrimeCenter and Kongsberg Cutting Tables Work Better Together

June 02, 2025

In today’s fast-paced print and packaging industry, efficiency isn’t just a competitive advantage—it’s a necessity. Print service providers are under increasing pressure to deliver high-quality results faster, with fewer resources and minimal waste. That’s where the synergy between Caldera PrimeCenter and Kongsberg cutting tables can be a game changer.

Why Print-to-Cut Integration Matters

Traditional workflows often involve multiple manual steps: preparing files, nesting layouts, adding cut paths, and finally sending jobs to the cutting table. Each handoff introduces the risk of error, delays, and material waste.

But what if your workflow could automatically handle prepress and finishing tasks with precision and speed? That’s exactly what the integration of PrimeCenter and Kongsberg delivers.

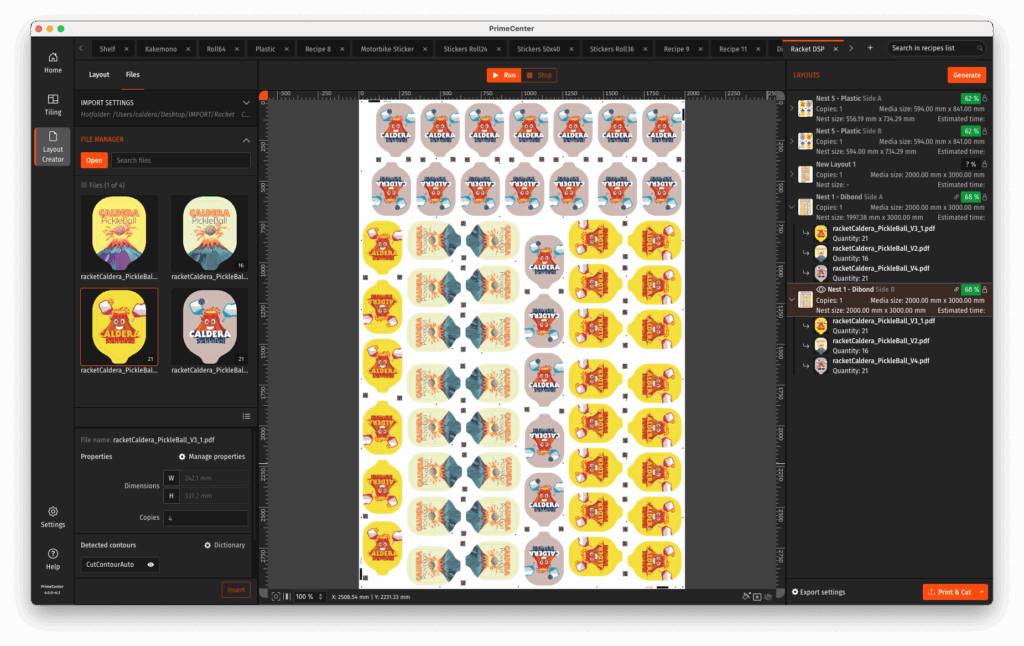

What Is Caldera PrimeCenter?

PrimeCenter is a powerful prepress software that streamlines job preparation. It handles:

- Preflighting: Automatically checks incoming files for errors.

- Nesting & Layout Optimization: Maximizes material usage.

- Cut Path Management: Creates cut-ready files tailored for your finishing equipment.

- Metadata Management: Organizes job data for better traceability and control.

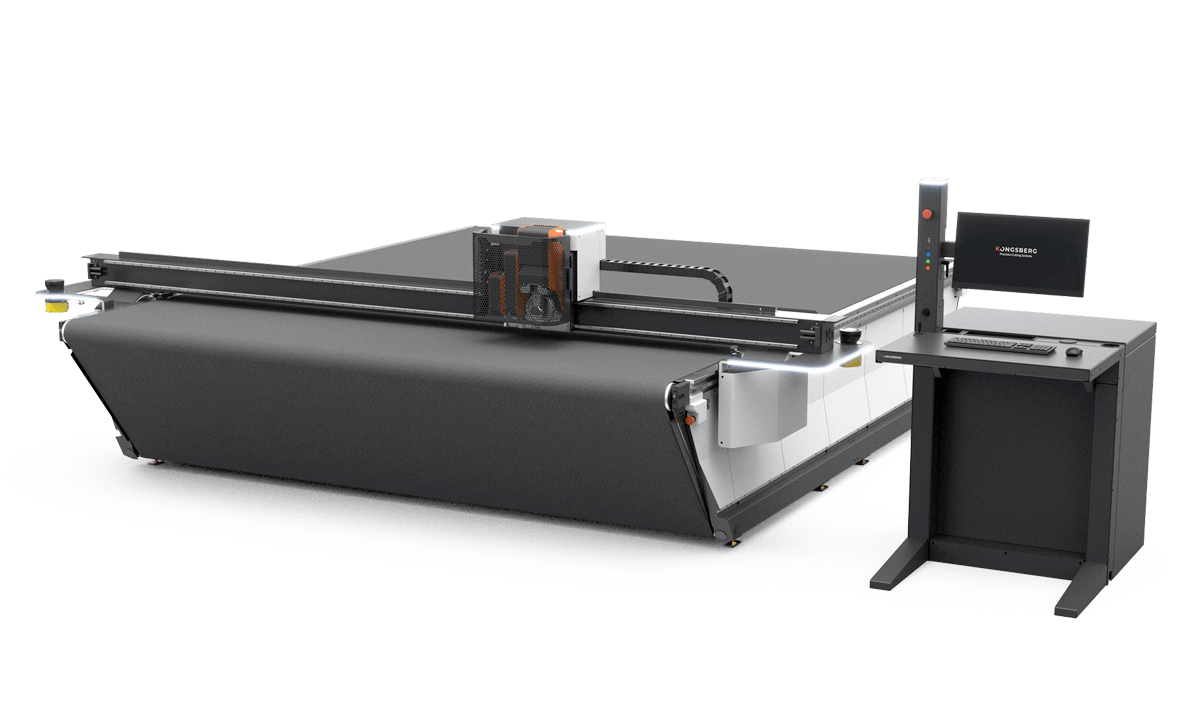

What Makes Kongsberg Cutting Tables Unique?

Kongsberg is known for its robust, high-precision digital cutting tables used in signage, display, and packaging production. These machines excel at:

- Handling a wide range of materials (corrugated, foamboard, acrylic, etc.)

- High-speed, accurate cutting and creasing

- Integration with digital workflows for reduced setup times

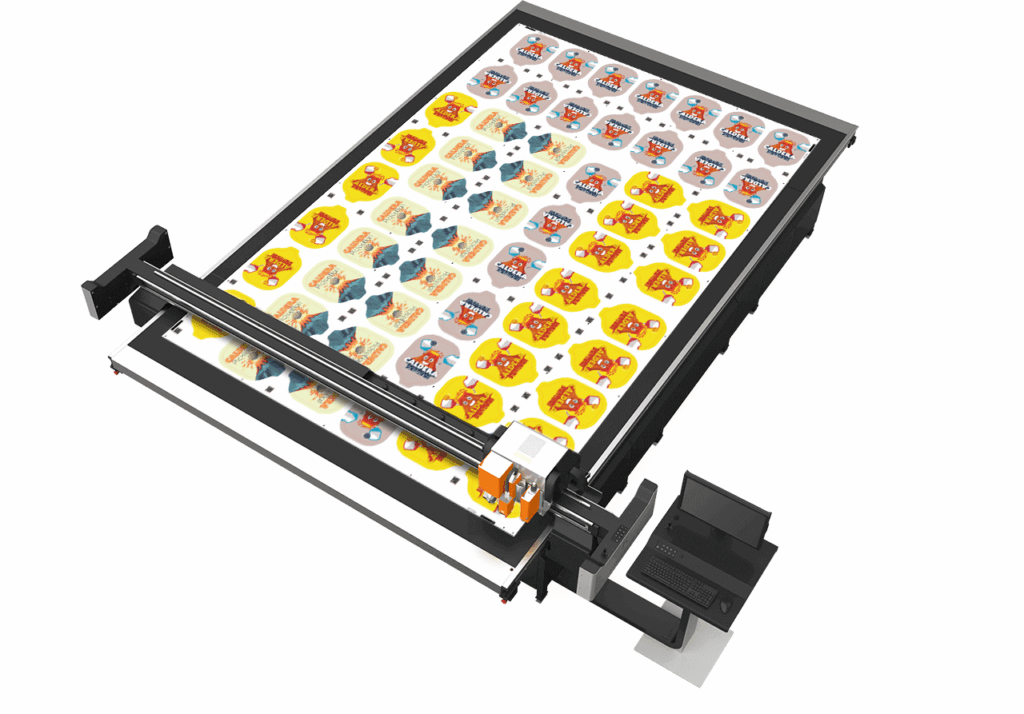

Better Together: The PrimeCenter + Kongsberg Advantage

When used together, PrimeCenter and Kongsberg form a simple, automated production loop. Here’s how:

- Automated File Prep: PrimeCenter generates files that are ready for cutting, that plug directly into Kongsberg’s workflow—no rework needed.

- Faster Production: Intelligent nesting and cut path optimization reduce setup times and speed up finishing.

- Waste Reduction: Optimized layouts ensure maximum material usage, reducing costs and environmental impact.

- Scalable Workflows: Whether you’re handling short-run packaging or large format display graphics, this integration supports complex, high-volume jobs with ease.

Real-World Impact

Production teams that adopt this combined solution report:

- Up to 30% faster turnaround times

- Significant reduction in manual errors

- Improved ROI on both software and hardware investments

Ready to Automate?

If you’re looking to streamline your print-to-cut workflow, the integration of Caldera PrimeCenter with Kongsberg cutting tables offers a future-ready solution. It’s automation that works—not just in theory, but in the real world of high-demand production.

Want to see how it can work for you? Contact us for a demo or workflow consultation.

Related articles