Streamline Prepress for POS Displays and Packaging with PrimeCenter

October 31, 2025

It’s always important to set up an optimized prepress process for packaging and point of sale displays (POS). Many prepress operators face multiple challenges when it comes to prepress workflows in packaging and POS display handling.

In a previous article, we talked about how car wrapping professionals benefit from PrimeCenter. In this article, we will explain what prepress is in the field of industrial displays and packaging, the challenges printers face, and how to solve some of these challenges using PrimeCenter workflow automation tools.

What is Prepress in Packaging and POS Displays?

In the context of point-of-sale (POS) displays and packaging, prepress refers to all the preparation work required before printing. This includes finalizing display and package layouts, editing files for print, managing colors to achieve brand consistency, and detecting potential errors in text, images, or layouts. You can read our article on prepress for more details.

For packaging and displays, prepress serves as the critical link between design and production, making sure that the final printed display or package is visually accurate, structurally correct, and ready for manufacturing. In this way, users prevent costly mistakes in the production process.

How a Disorganized Workflow Affects your Production

You will keep experiencing:

1- Print Errors on Packaging Materials

- Miscommunication or a lack of standard procedures can lead to mistakes in colors, text, or layout.

- These errors often require costly reprints or corrections, delaying the project timeline.

2- Delays in Product Launches

- Without a structured workflow, files may be misplaced, approvals delayed, or tasks duplicated.

- This slows down the entire production process and affects delivery schedules.

3- Higher Costs

- Errors, rework, and inefficient workflows directly increase production costs.

- Material wastage, extra labor, and rushed corrections can significantly impact the packaging budget you have.

The Main Challenges of POS Displays and Packaging Prepress Production

The complexity of producing POS displays and packaging keeps increasing. Shorter deadlines, multiple print technologies, and the demand for customized displays and packaging put significant pressure on prepress teams.

You might have already heard about some of these challenges:

File Preparation: Designers often submit files that need additional preflight checks and manual adjustments to ensure they are print-ready for POS displays and packaging.

Layout Optimization: Poor nesting and inefficient imposition increase packaging material waste and raise printing costs.

Workflow Fragmentation: Without automation, operators must manually handle repetitive tasks, such as adding marks, naming files, or exporting cut lines, slowing down POS display and packaging production.

Scalability: As job volumes increase, relying on manual prepress quickly becomes challenging for POS display and packaging production.

To perform well in a competitive market, POS display and packaging businesses need solutions that reduce repetitive work and create consistent, automated workflows.

How PrimeCenter Streamlines POS Display and Packaging Prepress?

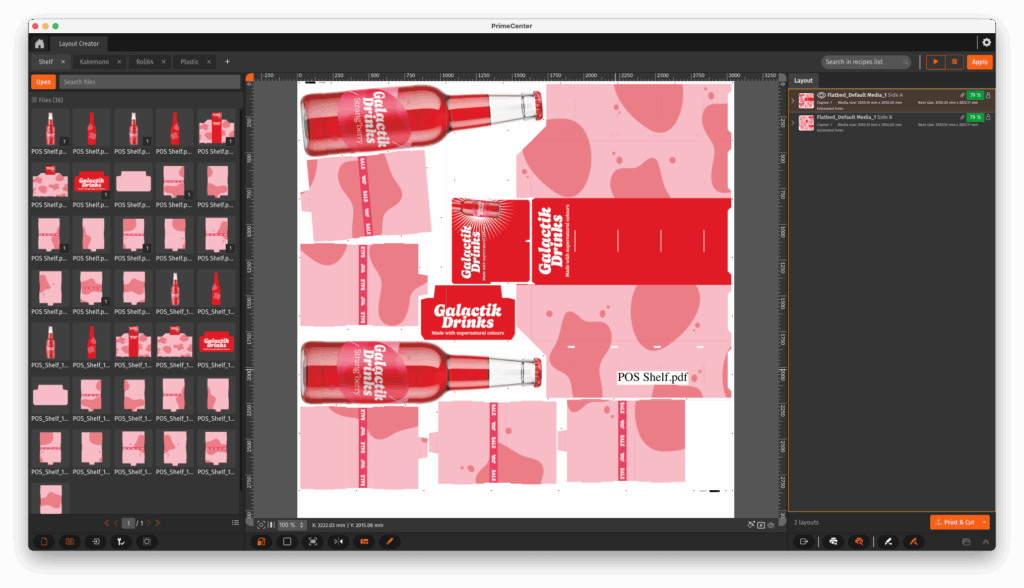

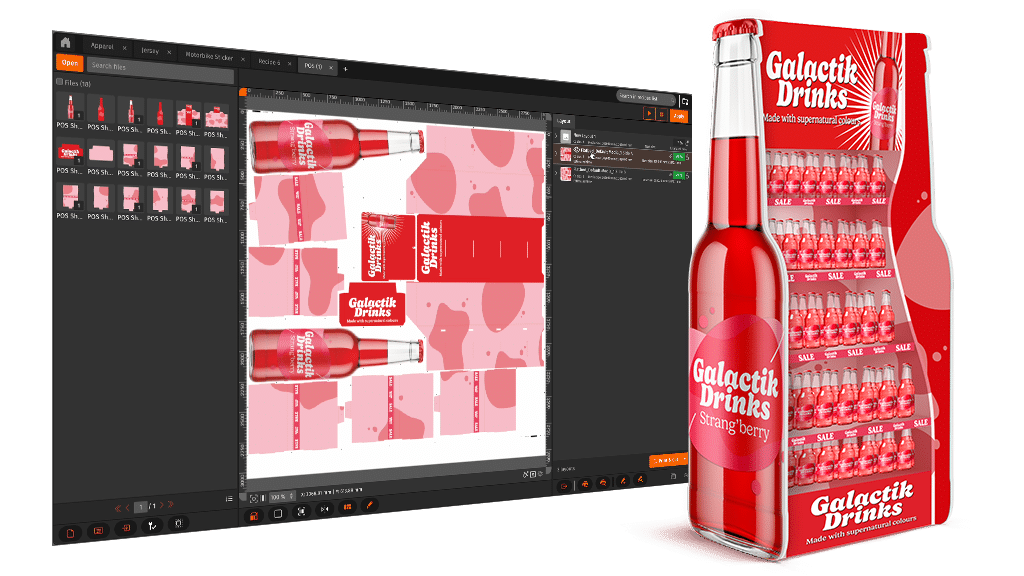

PrimeCenter is specifically designed to tackle the challenges of POS display and packaging production. It is an intelligent workflow automation solution that organizes jobs, prepares files for print and cutting, and ensures they are ready for the RIP or cutter for a smooth production.

1. Automated File Handling: PrimeCenter imports designs, verifies files, applies bleeds, adds marks, and cut lines for POS displays and packaging.

2. True-Shape Nesting: Its advanced nesting engine tightly arranges irregular shapes, minimizing material waste and maximizing media usage.

3. Recipe-Bleed Workflows: Users can create repeatable “recipes” for prepress operations. Once configured, the system automatically applies them to incoming jobs, ensuring consistency and saving hours of manual work for POS displays and packaging.

4. Smooth Integration: PrimeCenter can be directly used with major RIPs, printers, and cutting systems for a seamless production.

Interested in PrimeCenter?

Assemble each display and package carefully, maintaining a calm focus as you prepare for the next prepress workflow.

Related articles