What is prepress automation? and how Caldera PrimeCenter can help

July 24, 2025

The term “prepress” refers to the tasks you do before printing the final product. For instance, if you want to print a layout for packaging, you will need to go through several steps, which are called prepress. Now, what is Prepress automation? It simply means using software to handle the steps that happen before a job is printed or cut (prepress). These steps include:

- Checking and fixing PDF files (preflight)

- Renaming and sorting jobs

- Creating layouts for printing

- Sending files to the RIP and cutter

Traditionally, all this was done manually. But manual work takes time, creates delays, and increases the risk of mistakes. Using a prepress software, all these steps are automated. This means your production will be faster, more accurate, while involving fewer people who can handle the prepress automation software.

Table of content

Why prepress automation matters in printing?

Whether you print packaging, signage, textiles, or labels, you probably face the same challenges:

- You spend too much time preparing jobs.

- Operators make mistakes that cost time and money.

- You waste material due to poor layout or human error.

Advantages of prepress automation

Prepress automation is a method with many advantages. It will solve the challenges you face by:

- Speeding up job preparation

- Reducing human errors

- Improving layout efficiency

- Making production more predictable

The result? You save time, reduce waste, and increase profits.

What is nesting? And why is it important?

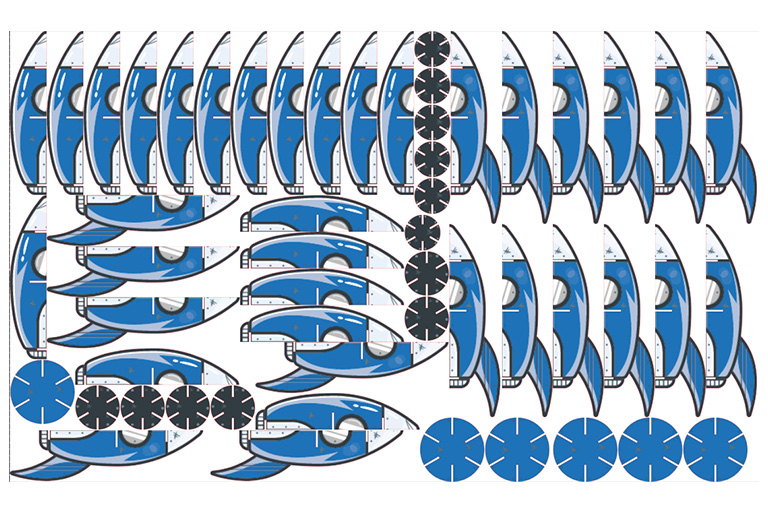

Nesting is the process of arranging shapes or jobs tightly together in a layout so they take up less space when printed or cut. This is especially important when using expensive materials like: Vinyl, Film, Textile, Cardboard, Acrylic sheets.

Without nesting

You waste space. Each job is placed with too much margin around it, leading to media waste and longer cutting times.

Without smart nesting

Jobs are arranged closely together, often using true-shape nesting, which means even irregular shapes are fit together efficiently. This saves up to 20% of material.

Where does PrimeCenter come in?

Caldera PrimeCenter is a prepress automation software focused on nesting and job preparation.

1- Automatically prepares print jobs

- Imports PDFs

- Preflights files

- Sorts jobs into queues

- Renames and groups them

2- Creates smart layouts using nesting

- Uses true-shape nesting

- Adjusts bleed and margins

- Arranges multiple jobs in one print run

Who should use PrimeCenter?

PrimeCenter is ideal for:

| Industry | Use Case |

| Packaging printers | Create nested layouts for folding cartons, labels, and boxes |

| Signage producers | Combine multiple customer jobs onto one board or roll |

| Textile printers | Arrange repeating patterns and cut lines efficiently |

| Screen printers & DTF shops | Batch jobs and reduce film usage |

What Are the Benefits of Using PrimeCenter?

| Benefit | Explanation |

| Save media | Nesting reduces material usage by up to 20% |

| Save time | Automate repetitive tasks like sorting and renaming |

| Reduce errors | Preflight and automated job preparation prevent mistakes |

| Handle more jobs | Batch jobs and speed up the layout process |

| Use your existing tools | PrimeCenter works with most RIPs and cutters |

Curious about PrimeCenter?

If you’d like to learn more about how PrimeCenter could benefit your business, contact us for a custom demo with our experts!

Related articles