How to make your DTF workflow more efficient

November 20, 2024

The Direct-to-Film market has grown rapidly in recent years, driven by increasing demand for short runs of customized apparel. However, while this growth is exciting, it also brings new operational challenges. Many print shops manually handle each step of the file preparation process, from design to print and cut setup. This time-consuming process can limit production capacity. As shops take on more jobs (often with repetitive requirements), the need for streamlined workflows becomes clear.

The manual approach is inefficient, increases the risk of errors, and leaves valuable production time on the table. As production scales, is there a smarter way to handle file preparation for Direct-to-Film printing and cutting? This article explores how to make your DTF production process faster, more precise, and less prone to errors.

Consider automating file preparation for Direct-to-Film

Manually preparing files is a significant pain point for many DTF printers. Whether you’re producing custom T-shirts, sportswear, or goodies, each job often requires specific cut vectors, bleed settings, and registration marks to ensure precise results. As more orders come in and production starts to scale, this can quickly turn into a serious bottleneck. Handling these tasks manually with Adobe Illustrator or CorelDraw is not only repetitive, it can also lead to inconsistencies and errors.

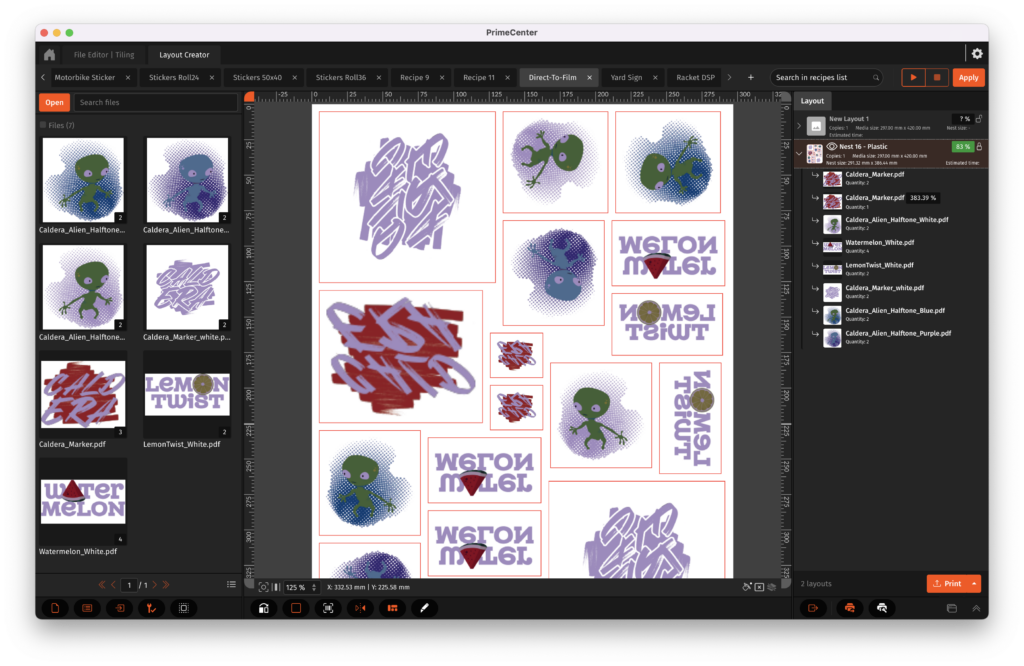

Imagine if you could prepare batches of DTF jobs automatically, adding consistent white underlayers, cut marks, bleed, and optical codes, all based on pre-set configurations for specific jobs or clients. Automating these steps would eliminate hours of manual file setup and reduce mistakes that lead to reprints. For print shops looking to grow, this kind of automation is essential for optimizing workflow and maximizing productivity.

If you’re manually preparing your files, it may be time to consider a prepress solution to simplify and automate these processes. It will reduce time spent on repetitive tasks, minimize human errors, and enable faster turnarounds. Perfect to improve your bottom line!

Swap manual cutting with automated cutting

When it comes to Direct-to-Film, many shops manually cut around their designs using scissors or craft knives. This method is less precise than a cutting plotter, though it can work for designs that don’t require exact cutting. The big downsides are the risk of manual errors and the time it requires to manually cut all your designs.

On the other hand, a cutting plotter is more efficient for cutting larger batches. It also allows you to achieve more precise results. But to be processed correctly by the machine, cut files must be prepared properly, with cut vectors, registration marks and sometimes optical codes to ensure proper detection from the machine, and precise automatic cutting.

Using a prepress software to automate cut file preparation is a game-changer for print shops seeking a reliable, professional finish while scaling up their production capabilities.

The Secabo DTF MultiCut Pro is an automatic cutter for Direct-to-Film.

Who can benefit from an automated DTF workflow?

Garment and apparel brands: Businesses that specialize in custom apparel, on-demand fashion, or promotional items can save time and reduce errors by automating file preparation tasks. This is particularly valuable when aiming for fast turnaround times.

High-volume DTF printers: For shops handling hundreds or thousands of prints daily, automated workflows reduce bottlenecks, allowing the team to keep pace with high demand without compromising on quality.

Print service providers expanding into DTF: Shops offering a variety of print services can use automation to manage the specific requirements of DTF production efficiently, minimizing the need for multiple software tools and streamlining their overall workflow.

Prepress automation: the key to streamline DTF processes

Optimizing DTF workflows is essential to keep pace with the growing demand. Automating file preparation tasks with a prepress software reduces the need for manual intervention and minimizes errors. This approach makes it possible to process more jobs in less time, freeing up resources to focus on other high-value activities.

When looking for a prepress software, seamless integration with your RIP software or peripherals—will benefit your entire workflow.

Caldera PrimeCenter is compatible with any RIP software and fully supports a wide range of plotters and flatbed cutters. Among the supported models is the Secabo DTF MultiCut Pro, an automatic cutter specifically designed for DTF workflows. Using PrimeCenter means you can prepare cut files tailored to your devices and automate your workflow from prepress to production.

If you’re ready to explore how automation can transform your DTF workflow, contact us for a custom demo!

Subscribe to our Newsletter

Stay in touch with our latest product launches, news and events.

Related articles