Throttle Syndicate streamlines production with Caldera solutions

July 09, 2024

Life in the fast lane with Throttle Syndicate

If you follow Professional Dirtbike Racing, you’ve seen Throttle Syndicate’s work at indoor and outdoor motocross events. Even if you don’t follow the sport, you’ve probably seen a dirtbike with their eye-catching decals near you. This motorcycle graphic company supplies and sponsors supercross teams. They also create custom graphics for anyone who wants to personalize their bike.

The experts in designer decals

The Production Manager at Throttle Syndicate, Victoria, explained the business to us. “Outside of supporting and sponsoring our race teams, we also accomodate the average rider in customizing their personal bikes. Custom orders make up much of their work. Most customers pick a design and add their name, number, and logos. If someone wants a unique look, they work with them to create a new design based on ideas and inspiration.”

To achieve this, Throttle Syndicate uses large format digital printers from Epson. “We have two SureColor S80600s,” says Victoria, “and we also use a Royal Sovereign heated laminator after printing the graphics. They use a thick 15mm laminate—the thickest available—to boost durability on racetracks, deserts, or technical hills. After lamination, we cut the graphics by piece using our Graphtec FCX-2000 flatbed cutter. Throughout this process, we’re using Caldera software to send the art files to both the printer and the cutter.”

What drives Throttle Syndicate?

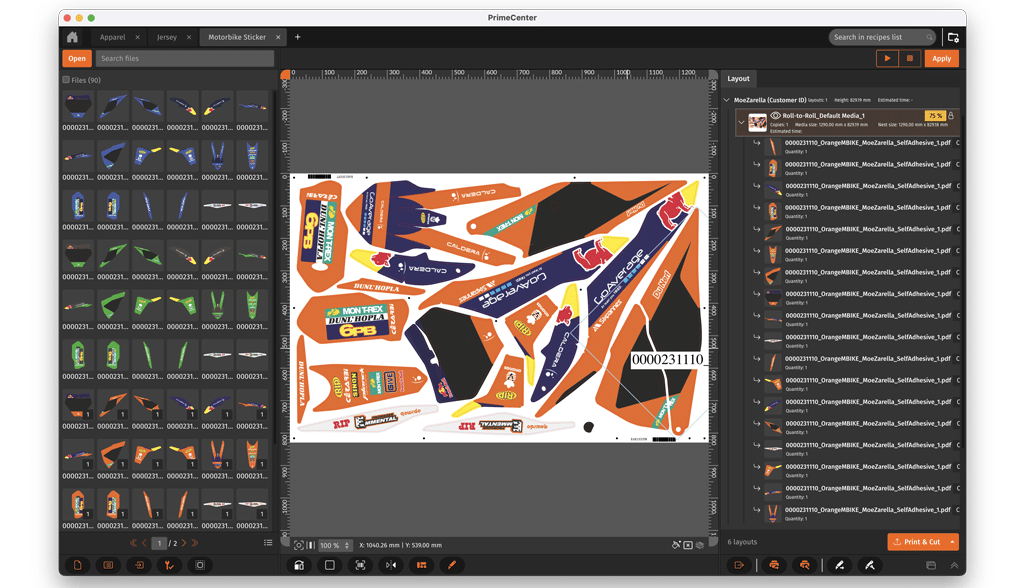

Throttle Syndicate has been using the Caldera RIP software for printing since they first opened their doors in 2018 and have recently extended their use of Caldera to its cutting operations when testing out Caldera PrimeCenter. Victoria says, “I’m really glad we gave PrimeCenter a shot. Our old cutting software was glitchy—it froze other programs whenever I opened a cut file and disrupted whatever I was doing until the job finished. So now, with Caldera’s VisualCut software, I can continue working in other applications while simultaneously sending art files to the cutter.”

Using Caldera has been a learning experience for the team. “In regard to the printers, Caldera enables you to do so much that at first, it was a little overwhelming. But it’s been great for us, as it means we can print on specialty materials along with other more unusual settings to achieve a specific look. We can save our print profiles and use them again with pre-made folders which, given the variety of materials we offer, is useful for digital organization. We print on regular white vinyl, clear vinyl and metallic vinyl and each one requires unique printing settings. The fact that Caldera can accommodate all this is one of the things I really like about it.”

“With Caldera’s VisualCut software, it creates a separate cut file for each art file and sends it straight into the queue. Each file is ready for cutting as soon as I open it. We now print each job with a barcode, so when I scan it, the software pulls up the cut file and immediately starts scanning for registration marks. Our production assistants save a lot of time in between jobs with this feature.”

Another area in which Victoria appreciates Caldera is in its PrimeCenter software. “I’ve found that PrimeCenter really helps cut down on production time in general, especially for the designers. They can now focus completely on design work and less on the preparation of each file for production. I think it saves even more time for quoting miscellaneous artwork with large quantities,” she says. “When outside designers send us random artwork for small decals, we just enter the quantity we need into PrimeCenter. It nests the designs in minutes and calculates exactly how many sheets we need to print. That process helps us avoid mistakes—especially when making sure we have the right number of pieces on each sheet to hit the total order.”

Support for the team

Throttle Syndicate finds value in another aspect of Caldera’s software. “We really appreciate all your guys’ help, especially in the transition to using PrimeCenter,” says Victoria. “It’s easy to feel overwhelmed by all the settings. However, the techs at Caldera, particularly Joey, really helped to get everything set up correctly to have us running smoothly today. Sometimes blog posts and guides aren’t enough—you really need someone to walk you through it. That’s why we appreciated having a live demo when we tested PrimeCenter.”

For Caldera, great customer support is always part of the deal, and our workflow specialist, Joey Phillips, is on a personal mission to make sure clients get what they need from the software. Because of it, Throttle Syndicate is up to speed with their production workflow.

Try our solutions

Contact us to book a demo with our workflow specialists!

Subscribe to our Newsletter

Stay in touch with our latest product launches, news and events.

Related articles