How does PrimeCenter make your printshop more profitable?

September 07, 2020

What is PrimeCenter?

PrimeCenter is Caldera’s prepress solution which aims to help wide format digital printers optimize job preparation for printing and cutting. Adapted to print shops of all sizes, PrimeCenter has been designed to optimize the full printshop workflow and help you save time and media. Let’s have a look at PrimeCenter’s main features and how they can help you out across your production!

The importance of nesting in digital printing

Nesting is a crucial step in job preparation for printing. It helps optimize machine capacity, reduce costs and printing time while increasing your productivity overall.

In the printing industry, nesting refers to the layout strategy allowing printers to organize the shapes of products to be printed or cut out on the available space of the sheet in an optimized way. The idea is to fit as many shapes as possible on the sheet in order to save media, time and money. When done properly, nesting helps you use the available resources in a clever way which means less media waste.

Prime Nesting: save time and media with smarter layouts

The nesting process doesn’t have to be made manually. Indeed, several nesting methods are available in PrimeCenter. With the True Shape Nesting, the software’s algorithm automatically analyzes the shapes you want to print and nests them in a perfectly optimized layout, as shown in the example below:

Ganging: make job and order management easier

If you manage several projects coming from different customers at the same time, PrimeCenter’s ganging feature will be a life-changer. The software can automatically group together files based on a specific metadata of your choice, for example the customer’s name. It will then automatically nest them together in different layouts. This feature will help you save time during job preparation and ease your overall order management process.

Preflight: fix problems early on to save money

The term preflight was coined after the aeronautical industry. Before taking off, pilots usually do a pre-flight check to make sure everything works the way it should. The same principle is applied in the printing industry. The goal of the preflighting process is to fix problems as early as possible during the prepress stage in order to save money and avoid errors.

Indeed, one small design problem can potentially impact all the entire production process, resulting in costly errors. You want to make sure the problems are fixed before printing, otherwise the printed job will be rejected and priceless. The main problems encountered during preflighting usually are: missing images, missing fonts, transparency and color issues or resolution.

Preflight is a very important step to ensure a streamlined production workflow, which is why Caldera PrimeCenter embeds the powerful Callas Preflight Engine to ensure you are processing compliant PDF files.

Improve the cutting stage with PrimeCenter

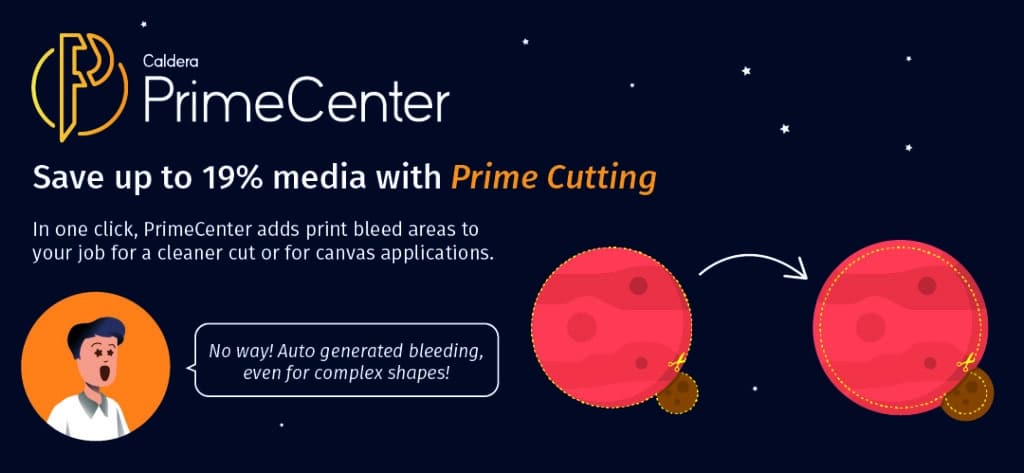

PrimeCenter also provides interesting features for the cutting part of production. The most interesting of them is the automatic generation of print bleed around all types of shapes in order to improve the finish aspect.

Also, the software is fully compatible with Zünd Cut Center.

Making sure everything is perfect before production is key in order to make sure printed products match the designer’s expectations. Caldera PrimeCenter has been designed to ease the pre-production stage using artificial intelligence and automation.

Related articles